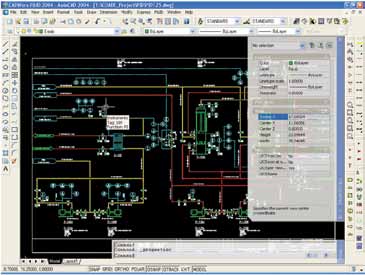

(P&IDs) Intelligent Process & Instrumentation Diagrams

Intelligent process & instrumentation diagrams (P&IDs) are graphical representations backed by a database containing all project management data. This pairing of sophisticated electronic tools allows useful organization and timely retrieval of process and facility data.

PEHTC, uses intelligent P&ID data for:

- Automatic report generation

- Reports during design, construction, maintenance, & management of the facility, including:

- Equipment lists

- Equipment specification sheets

- Line lists

- Manual & automatic valve lists

- Motor lists

- Instrumentation lists

- Customized reports in formats defined by the end user

- Flexible, expandable databases as part of a customized Microsoft® Access database

- On-line updates to existing reports — to reflect the most recent data revisions

- Bi-directional updating of drawings & the project database

- Single data entry is automatically applied throughout project database

The bi-directional dataflow between P&ID graphics and the centralized database provides a powerful design and management tool Ð especially during the initial stages of process and instrumentation design. Engineers and/or clients can see updated graphics and reports immediately, as project team members, facility technicians, and maintenance personnel provide input and changes. P&IDs thus form a solid foundation on which to build process management systems and procedures.

Advantages of Intelligent P&IDs:

- Input data only once, & then retrieve the data for use throughout the facility life cycle

- Populate the database with interactive drawings (i.e., from Auto CAD®), a customized database application (i.e., Microsoft® Access), or both concurrently

- Store facility data in an Open Database Connectivity (ODBC) compliant database

- Break down large projects into multiple smaller projects while maintaining one database

- Generate process data designed for direct application to OSHA 1910, EPA, & ISO compliance & reporting